Subtleties of Pumping With Gears (2024)

Inside the many pumps around the world lie a variety of methods to push liquids each with their own advantages and drawbacks. Gears have this strength of mechanical force, but so much relies of what doesn’t appear at first glance. So many tolerances and GD&T to have a dance of probable locations of every object at any point of rotational movement.

Sealing well long-term is the objective in pumping that is worth the significantly additional design and manufacturing cost. Most pumps wear out over a few thousand hours of use, but what it take to land something so reliable it lasts multiple years with confidence is long term testing with fully stabilized designs and manufacturing quality.

Massive EV Power Requires Cooling! (2021-2023)

Having the reigns on 500 electric horsepower is a hair raising experience even if the reigns are digital ones. The winding noise of electric motors spooling up to 12,000rpm through gear reductions to dragster tires being forced downwards on a dyno is an exhilarating sound and vibration felt throughout the building. So much power needed so quickly that not even industrial line voltage at the amperages we could get could keep up, batteries with very high discharge capacities had to be engineered and assembled for the purpose.

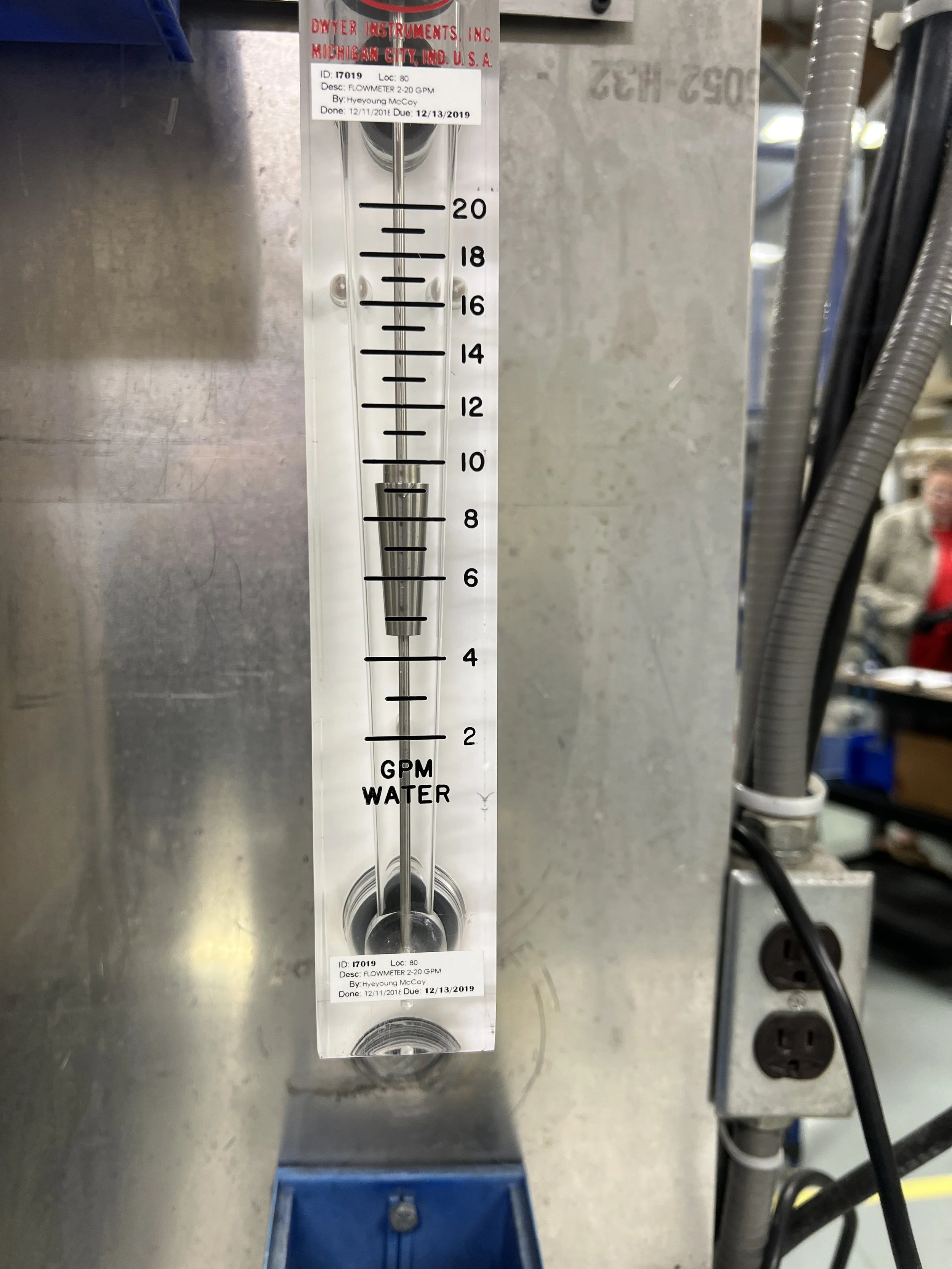

All these fun moments can only be moments though without an enormous amount of cooling. Even as efficient as electric motors are, they still shed off ~5-20% inefficiency to their environment, namely, heat. Air cooling can’t nearly keep up even with putting large fans, and putting massive mass-sucking motor frames of cast iron like Baldor motors isn’t desirable at all for vehicles, let alone ones you want to be fast… So you have to use a liquid with a higher ability to carry energy and remain stable at high temperatures. Water-Glycol antifreeze just would boil too easily for motor hotspots, so you have to use an oil. BUT…. you have to use an oil that is dielectric, or not conducting of electrical current. The current industry standard for electric motor cooling is using Dexron VI ATF for all of the reasons listed plus it isn’t a rare/expensive commodity.

My challenge and playground for a solid year was experimenting with changing cooling paths and methods to gain an edge in fringe applications where either speed is low or very high making pumping a difficult thing to optimize for if pump is driven off motor speed. Methods of reversal and heat exchanger selection and pump sourcing and finding the newest options coming out for EV’s got me excited for the design possibilities.

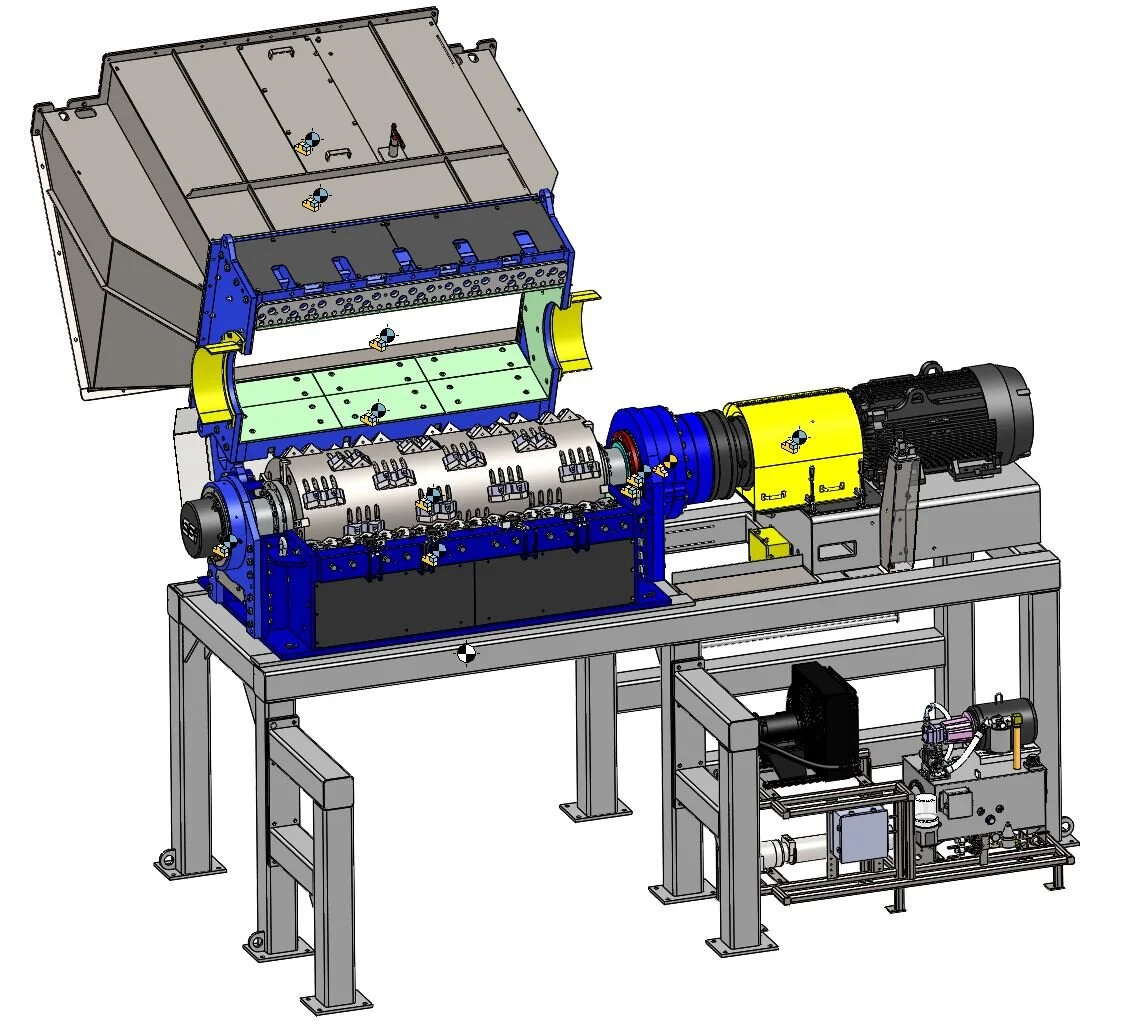

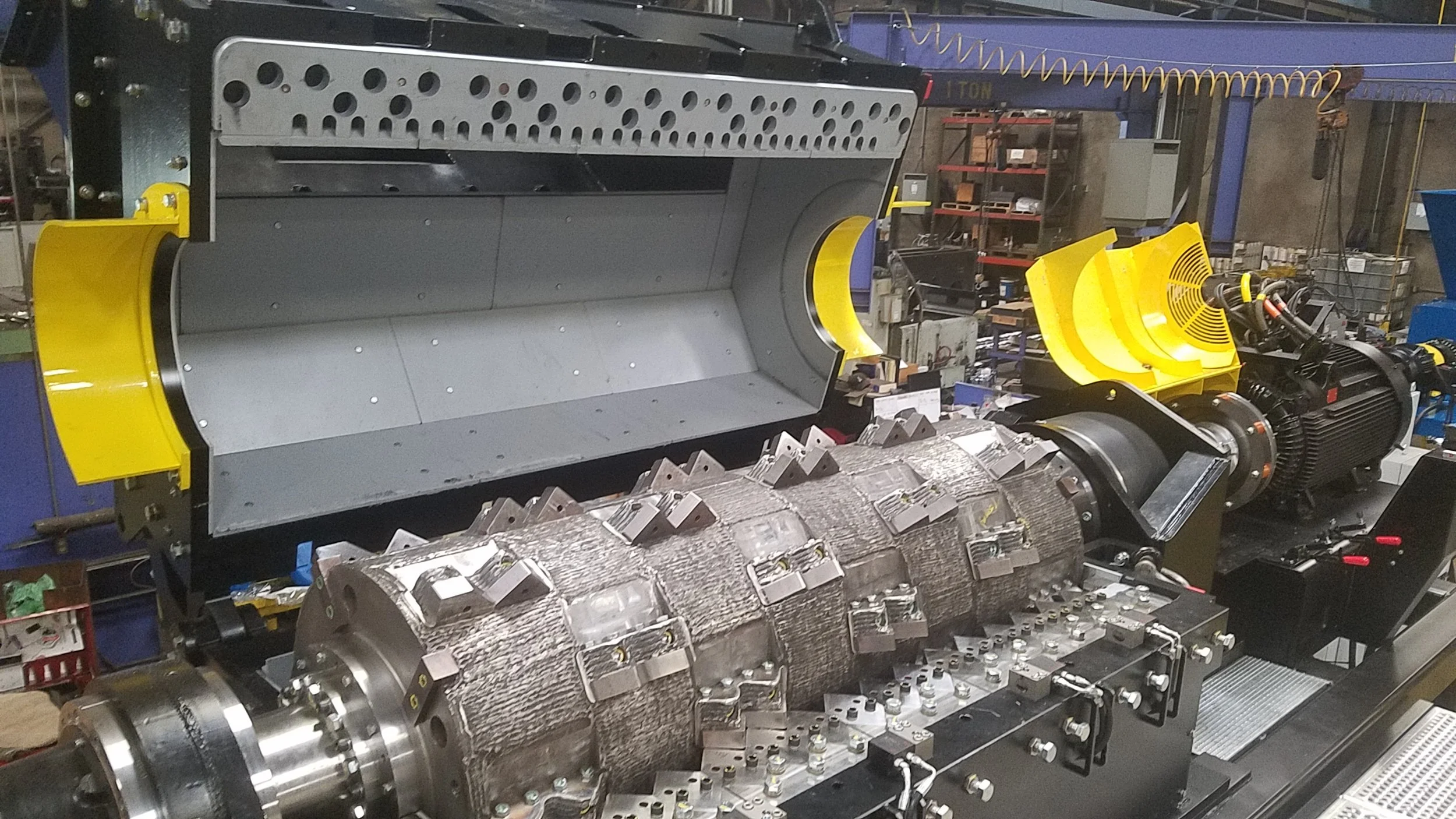

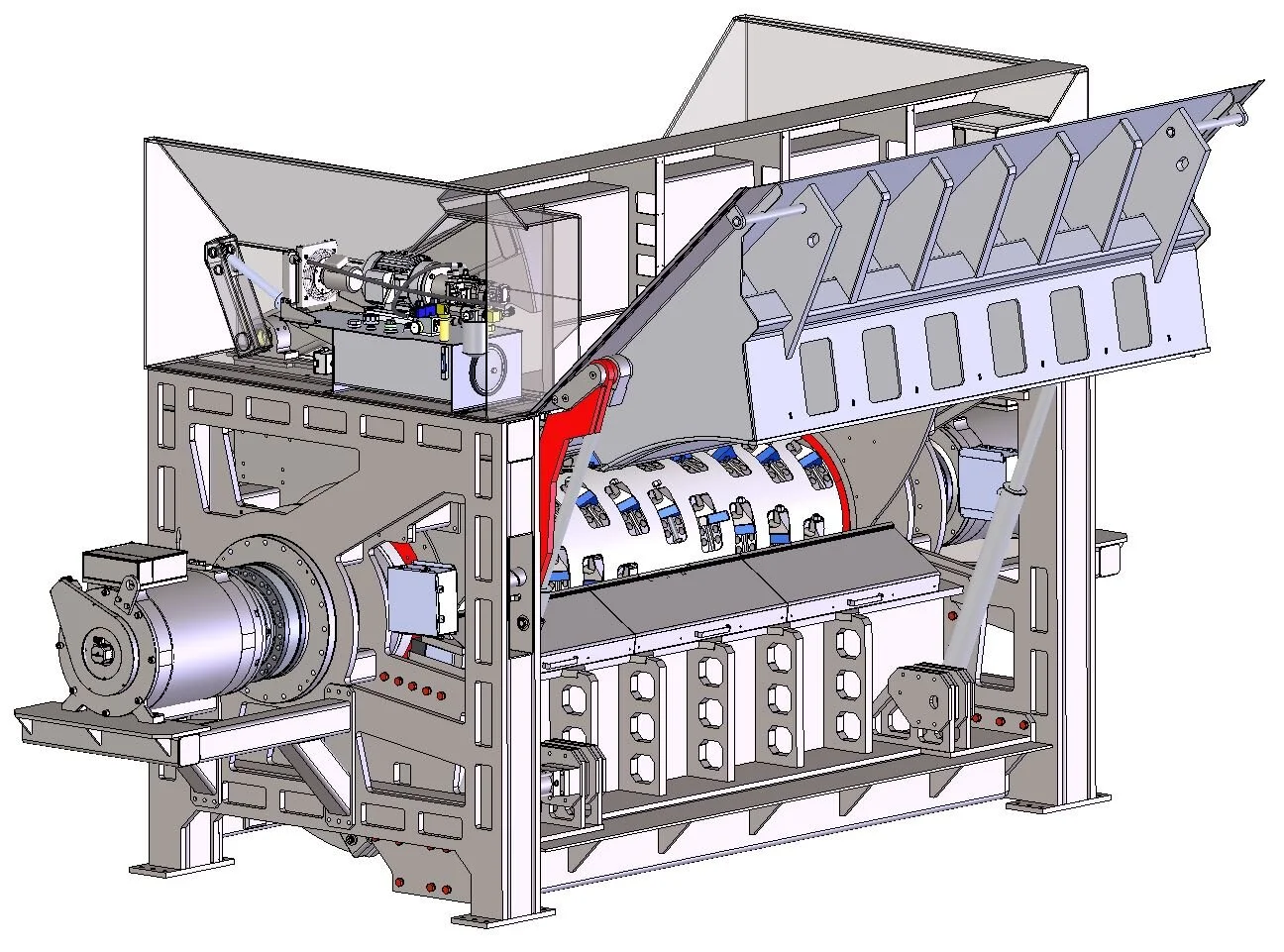

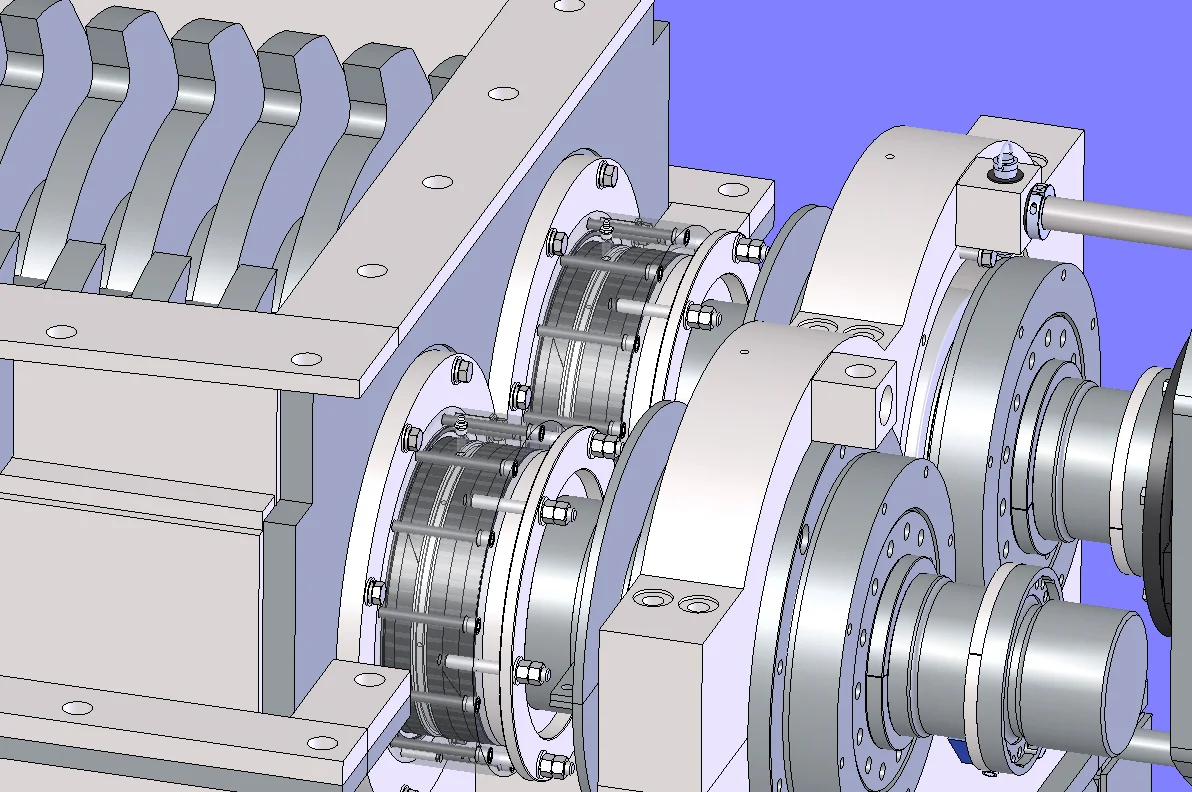

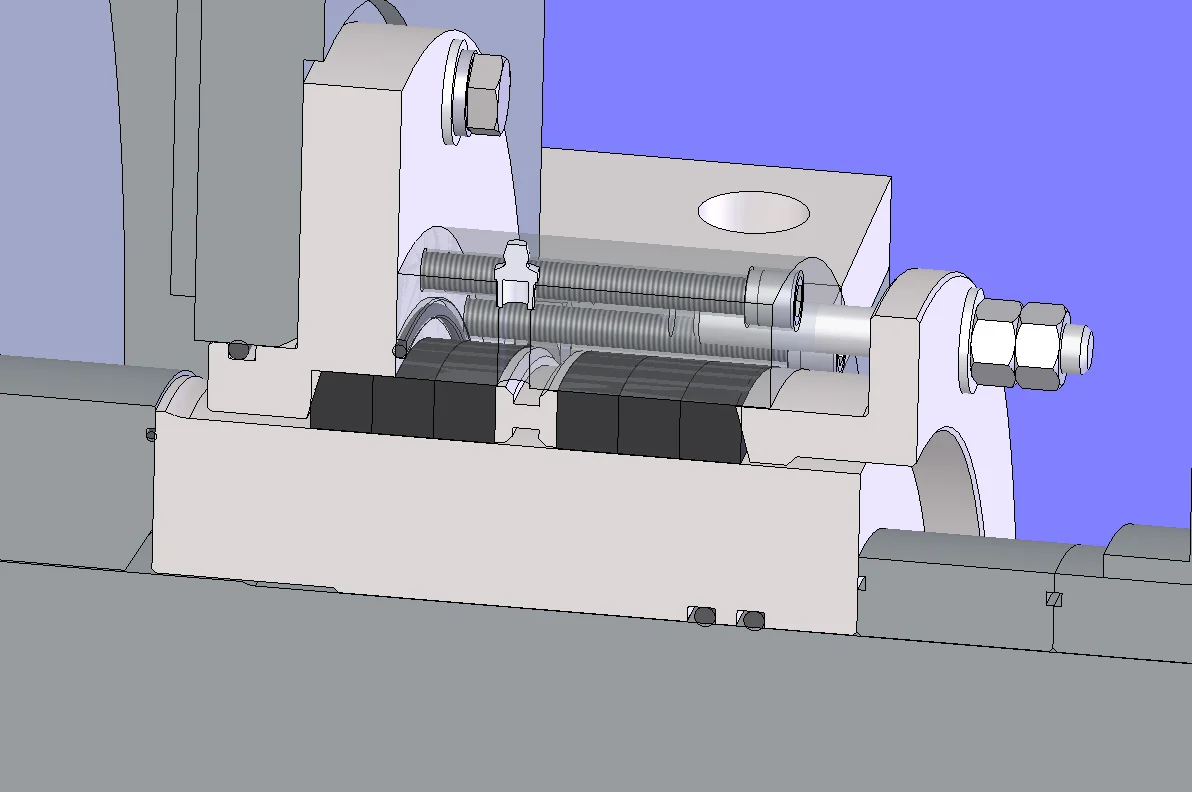

Big UniShears (2017-2021)

Being the Product Manager for single-shaft shredders has been been my job description for 3 years, and turning around products from dormancy to hot products has been an incredible blast. The Uni-Shears, as we call them, are hulking machines, easily weighing 20 tons for the completely revised SR900, and over 30tons for the planned SR1000 entirely designed by me.

When it comes to problems encountered by a 400hp shredder processing the most abrasive materials on the planet, the problems come in waves. But when each challenge is encountered we just find the next area to over-build and innovate with. I have enjoyed a fast-paced product development cycle and communicating directly with the customers to get the details that shape our next design.

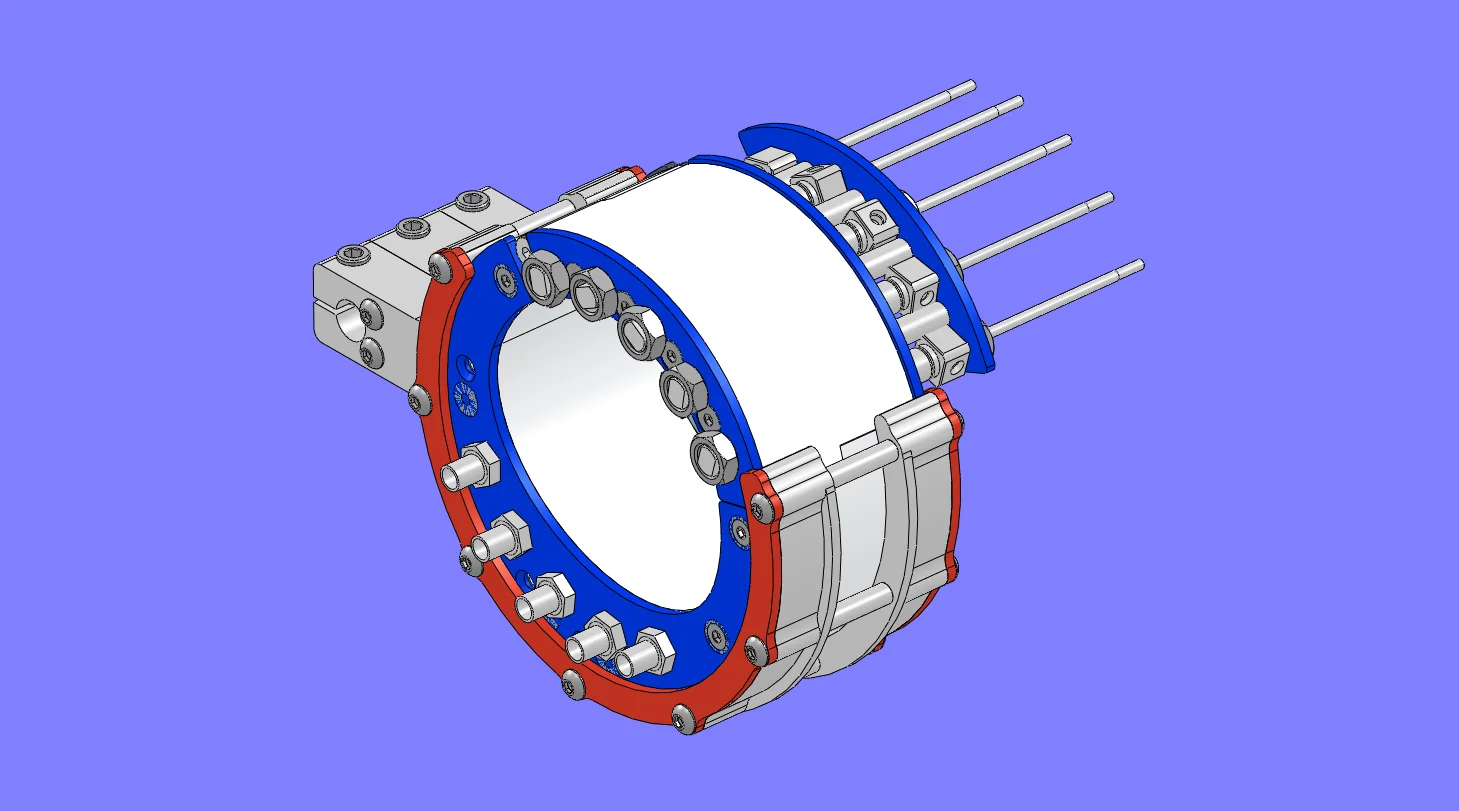

The SR900 System, complete with hydraulic chamber locking and opening for service access.

SR1000 preliminary designs for a shredder that can handle everything and offer dream-level amounts of service access.

When it comes to designing machines with high rotational inertia, figuring out the duty cycle of shock levels the bearings and frame will be subjected to is difficult. Its not like we have a smooth load like pumping water uphill. I have used theoretical energy calculations as well as practical experience from other high speed machine’s successes or failures to find a safe zone to size the components for. Finding success in a world where the machines are intentionally abused to the limits is very rewarding work!

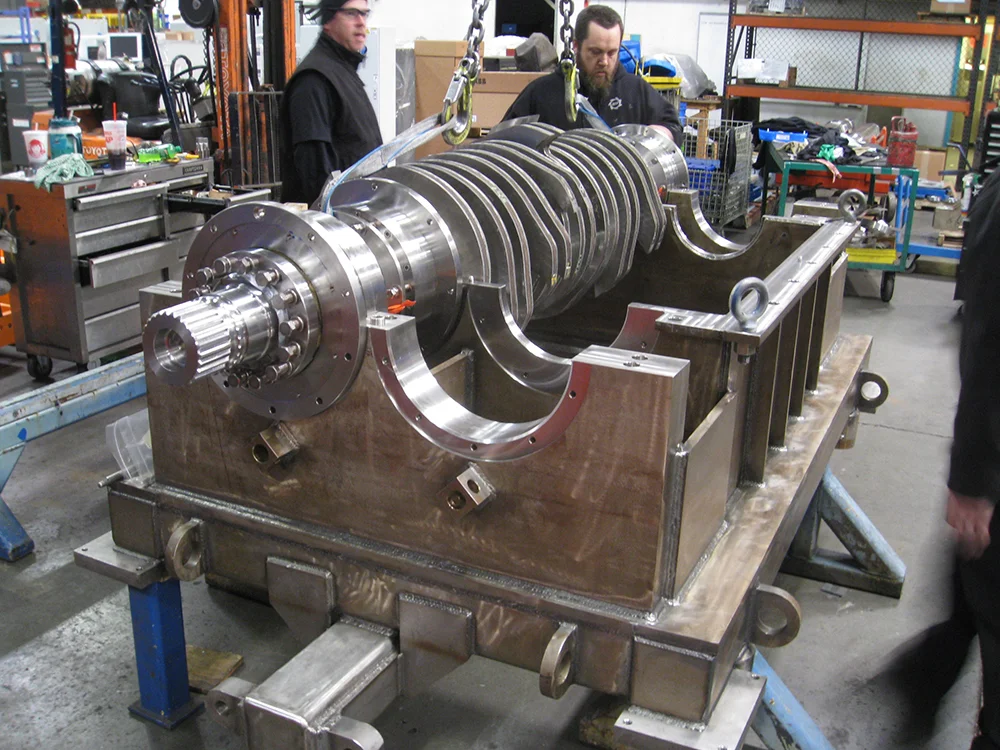

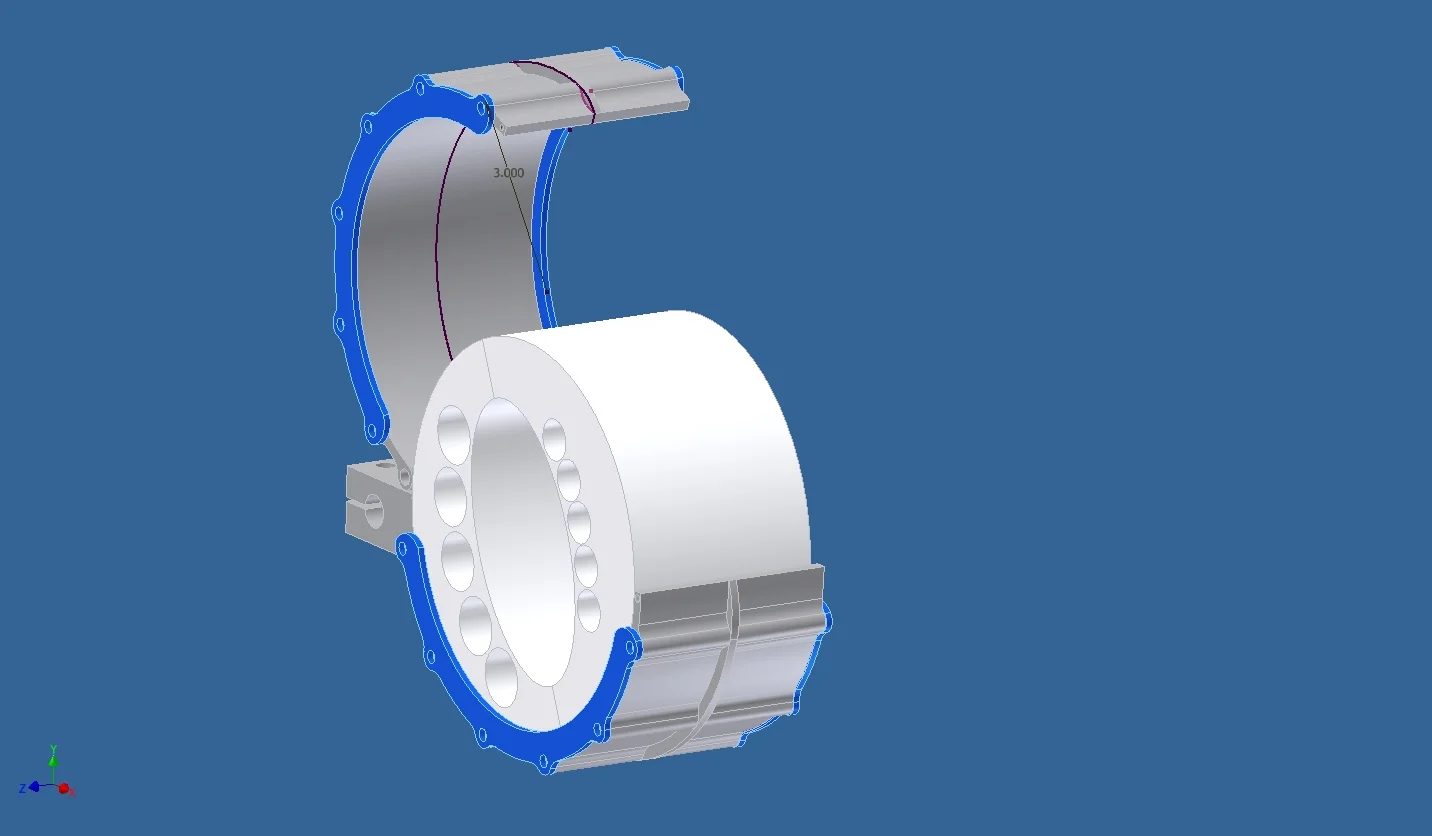

Stainless Mining Shredder (2013)

During my time at Shredding Systems Inc, I've worked extensively with Solidworks to design shredders, support equipment, and manufacturing equipment. I was also tasked with updating designs on problematic applications. One such project that gave continual challenge was a shredder required to work 24/7 in a hot surfuric acid environment, breaking apart rock.

The seals had been failing for years having gone through multiple methods and designers each no more successful, causing the machine to leak and corrode till nothing remains. The task was handed to me to manage this project to increase lifespan of the million dollar machine and solve the shaft seals problem.

I dove in. I fully modeled the existing Autocad designs, and ironed out the manufacturing process so future engineers would instantly be able to start on future manufacturing. The seals required complete analysis and evaluation, and ultimately I changed materials and the whole subassembly to a more robust and simple system. The results were perfect. The customer was thrilled with the reliability and ease of service as well. A reduction in cost was just icing on the cake.

Will it shred? →

Formula Hybrid Competition (2006-2010)

This project was the most intensely challenging, yet equally rewarding thing I've ever been a part of. The goal was to learn, plan, design, manufacture, test, and compete a hybrid vehicle at a international competition held for such vehicles; all done outside of university studies at IIT (Illinois Institute of Technology). The competition was scored by design, speed of the racecar, business proposal, and aesthetics.

See my photo-essay →

Honda CB650

More than a hobby. Less than four wheels.

Catching the two wheel fever

I think it started with a flying dream. It kept me thinking throughout the day, and when I got a call out of the blue to go help inspect and load a motorcycle my friend was buying, it planted a seed. Later that day I was loading another motorcycle, this time it was mine. It had oil leaking and a soft clutch and broken parts and wiring everywhere I looked. But it had me smiling. I can fix anything if it can make me fly.

It was a 1979 Honda CB650, an odd size engine that wasn't too popular and this bike hadn't been cared for in its last 32 years. The rebuild started with the wiring which shorted and melted the majority of the harness on the second ride I had taken it out. It needed every serviceable part changed and still needed major work. It was a miracle I had lived through the ride home. It had a glamour that needed instagram filters to uncover.

Hand rehabilitation device 3000

Stroke victims suffer many sorts of difficulties, but when someone loses hand strength, life becomes far more difficult. One common type of strength loss is with the ability for the hand to open and lift objects, but still having retained strength in the opposite of grabbing and pulling towards you. This is particularly frustrating for a patient because for example you can hold a cup but not open your hand to wrap around the cup. In addition support is needed for the patient to raise their arm upwards.

Illinois Tech was asked as a senior design course to task a group look at this problem and make something that would help. The device pictured is what we designed and built in one semester.

It had to retain rotation ability, have adjustable force mechanisms for each digit, be useable by a possibly elderly and weak individual, and to look attractive.

The challenge was taken on and a small dedicated group completed the first fully functional and rehabilitative prototype. To be able to help someone regain even a portion of their former function and independence was a special experience and opened the eyes of some young engineers to how those in the medical field feel when helping someone.

Ballista Pumpkin Launcher (2005)

Every Halloween, there's a competition held at IIT to build a device that throws a pumpkin the furthest. The method my team devised (above) was the only of its kind that year and every year since. This crossbow/ballista type thrower is far more difficult to build and design than a simple catapult. The forces involved are a significantly higher and managing them takes a great deal more design work. The truck leaf springs used on the ballista held so much energy when fully inverted that it took two people to wind the winch back to firing position. It fired a large pumpkin 190ft (58m), the furthest of any rule abiding team that day.